SEARCH

New process for more efficient recycling of plastics

SHARE IT

The accumulation of plastic waste in oceans, soil or even in our bodies is one of the biggest environmental problems of the modern age, as there are more than 5 billion tons of such plastics. Despite the enormous efforts made to recycle plastic products, the actual exploitation of these materials remains a great challenge.

A key problem with plastics concerns their diversity and the different chemical processes that must be done to make them materials for reuse. Proper sorting of plastic waste is practically impossible to do on a large scale and that is why huge landfills have been created with plastics waiting to be recycled.

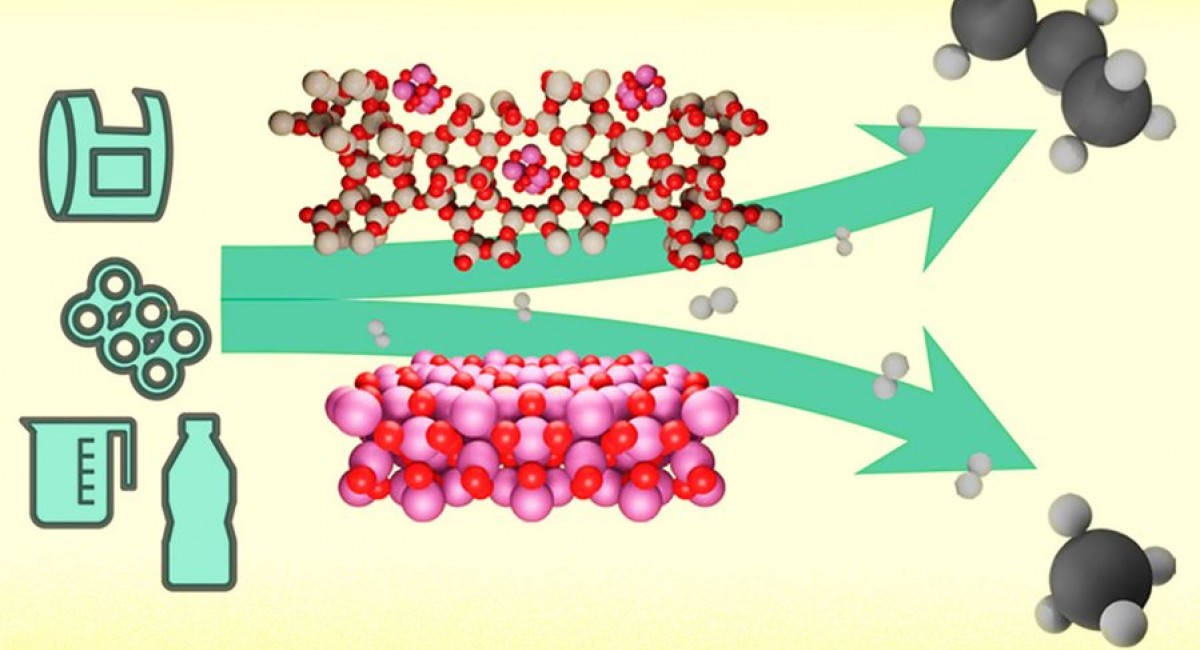

That's what a team of MIT researchers aspire to change, which has developed a new type of catalyst based on combining zeolite with cobalt nanoparticles. The use of this catalyst has proven to be extremely efficient in breaking down the most common forms of plastics (PET and PP) into propane, which in turn can be used as an affordable fuel for furnaces, heaters, vehicles, or even as an ingredient in the production of new plastic materials.

The researchers note that the catalyst is very easy to use on a large scale and at low cost, as zeolites and cobalt are fairly cheap materials and widely distributed in nature. Among the advantages is the fact that the process is completely clean, meaning no methane products are produced.

MORE NEWS FOR YOU

Help & Support

Help & Support